P91 Alloy Steel Seamless Pipe, A335 gr P91 Welded Pipe manufacturer in India

Alloy steel P91 pipes are similar to other austenitic stainless steel alloys, where cold working helps in the enhancement of the overall tensile and creep strength. While other annealed materials tend to form stringy chips, this P91 grade of alloy steel machines more easily due to its higher degree of cold working. LG pipes and tubes is a Mumbai based company, renowned trader, supplier, and stockiest of alloy steel p91 pipes along with other grades of steel pipes and tubes. We possess an extensive inventory of various grades of pipes to meet our customers’ demands on a daily basis. All our products go under strict testing and quality checks under our expert’s supervision. We believe in quality products and so we use high end raw materials for all fabrications.

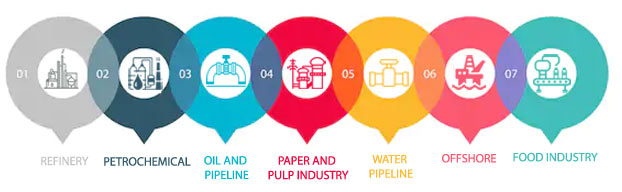

The product works best to its capability under extremely heated temperatures and provides high pressure bearing capacity in various environmental conditions. P91 grade alloy is fabricated using the latest tools and technology which helps it work wonders in various commercial applications. It is extensively used in power plants, nuclear plants, chemical industries, industrial boilers, condensers, and various commercial sectors due to its possession of global specifications. All our products are protected with different anti-corrosives like oil, black paints, and galvanized finish.

We provide customization of our products rendering to customers’ needs and demands. Where the P91 alloy comes in different sizes ranging from ½” NB to 36” NB, also has different forms like round, rectangular, square, hydraulic, and more. It also has different ends, dimensions, shapes and, lengths. The ferritic alloy possesses extensive chemical and mechanical properties which add more substance to the product. With a minimum tensile strength of 585 MPa and minimum yield strength of 415 MPa. The improved strength of the metal helps it resist various and natural corrosions and inhibits pitting. The alloy endures higher temperatures up to 600 Degree C and has a minimum of 20 percent elongation.

Table of contents

- Specification of A335 P5 Pipe

- UNS K41245 Pipe Price in India

- Application of Alloy Steel Grade P5 Pipe

- Types of P5 Alloy Steel A335 Pipe

- ASTM A335 P5 Pipe chemical composition

- Mechanical properties of Alloy Steel P5 Pipe

- ASTM SA335 P5 Pipe Equivalent

- A335 Alloy Steel P5 Seamless Pipe

- Products of Alloy Steel Gr.P5 Pipe

- Weight chart of ASME SA335 High Pressure Alloy Pipe

- Alloy Steel P5 Chrome Moly Welded Pipe

Specification of A335 P91 Pipe

| ASTM A335 P91 Pipe Size | 1/2” NB to 36” NB |

| ASTM A335 P91 Pipe Standard | ASTM A335 P91, SA335 P91 (with IBR Test Certificate) |

| ASTM A335 P91 Pipe Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| ASTM A335 P91 Pipe Thickness | 3-12mm |

| ASTM A335 P91 Pipe Tolerance |

Cold drawn pipe: +/-0.1mm

Cold rolled pipe: +/-0.05mm

|

| ASTM A335 P91 Pipe Origin | European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| ASTM A335 P91 Pipe Type | Seamless / ERW / Welded / Fabricated |

| Craft | Cold rolled and Cold drawn |

| ASTM A335 P91 Pipe Length | Standard Double & In Cut length also. |

| ASTM A335 P91 Pipe available in Form of | Round, Square, Rectangular, Hydraulic Etc. |

| Specialized in | Large Diameter ASTM A335 P91 Pipe |

| ASTM A335 P91 Pipe End | Plain End, Beveled End, Treaded |

| Application | Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

| Additional Testing | NACE MR 0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, H2 SERVICE, IBR, etc. |

UNS K11522 Pipe Price in India

| Size | MSL Make | JSL Make | ISMT make |

|---|---|---|---|

|

1/2"

|

4,264.71

|

4,272.06

|

4,257.35

|

|

3/4"

|

4,044.12

|

4,051.47

|

4,036.76

|

|

1"

|

3,897.06

|

3,904.41

|

3,889.71

|

|

1.25"

|

3,852.94

|

3,860.29

|

3,845.59

|

|

1.5"

|

3,750.00

|

3,757.35

|

3,742.65

|

Application of Alloy Steel Grade P91 Pipe

Alloy Steel Pipe suppliers

ASTM A335 P91 Schedule 40 Pipe

ASTM A335 P91 Schedule 80 Pipe

ASTM A335 P91 Schedule 60 Pipe

ASTM A335 P91 Square Pipe

ASTM A335 P91 Rectangular Tube

ASTM A335 P91 Square hollow section

ASTM A335 P91 Seamless Pipe

UNS K11522 Welded Pipe

High Pressure P91 Boiler Pipe

ASTM A335 Alloy Steel P91 ERW Pipe

ASTM A335 grade P91 Pipes

ASTM A335 P91 Alloy Steel Pipe

Alloy Steel P91 Chrome Moly Pipe chemical composition

| Alloy Steel P91 | C | Cr | S | Si | Mn | Mo | P |

| 0.05 – 0.15 | 1.00 – 1.50 | 0.025 max | 0.50 – 1.00 | 0.30 – 0.60 | 0.44 – 0.65 | 0.025 max |

Alloy Steel Grade P91 Pipe mechanical properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation |

| 415 min | 205 min | 30 min |

SA335 P91 Pipe Tensile Requirements

| Seamless | |||||

|---|---|---|---|---|---|

| P-5 | P-9 | P-11 | P-22 | P-91 | |

| Tensile Strength, min., psi | |||||

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | |||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

P91 ASTM A335 P91 Square hollow section Heat Treatment Requirements

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 – 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P911 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

| Quench and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

Alloy Steel P91 Pipe Equivalent

ASTM A335 Alloy Steel P91 Pipe equivalent

| ASTM International | BSi - British Standards institute | Material |

|---|---|---|

| A335 Gr. P5 | 3604/625 | 5% Cr 1/2% Mo |

| A335 Gr. P9 | 3604/629 | 9% Cr 1% Mo |

| A335 Gr. P911 | 3604/621 | 1 1/4% Cr 1/2% Mo |

| A335 Gr. P91 | 3604/620 | 1% Cr 1/2% Mo |

| A335 Gr. P22 | 3604/622 | 2 1/4% Cr 1% No |

| ASTM | ASME | Equivalent material | JIS G 3458 | UNS | BS | DIN | ISO | ABS | NK | LRS |

|---|---|---|---|---|---|---|---|---|---|---|

| A335 P91 | SA335 P91 | T91, K90901, X10CrMoVNb9-1, 1.4903 | K91560 |

| MATERIAL | SPECIFICATION | |

|---|---|---|

| ASTM | ASME | |

| CHROME- MOLY ALLOY STEEL PIPE NOMINAL WALL SEAMLESS | A335 Grade P911 1-1/4% Chrome; ½% Moly | SA335 Grade P911 1-1/4% Chrome; ½% Moly |

| CHROME- MOLY ALLOY STEEL PIPE NOMINAL WALL SEAMLESS | A335 Grade P22 2-1/4% Chrome; 1% Moly | SA335 Grade P22 2-1/4% Chrome; 1% Moly |

| CHROME- MOLY ALLOY STEEL PIPE NOMINAL WALL SEAMLESS | A335 Grade P5 5% Chrome; ½% Moly | SA335 Grade P5 5% Chrome; ½% Moly |

| CHROME- MOLY ALLOY STEEL PIPE NOMINAL WALL SEAMLESS | A335 Grade P9 9% Chrome; 1% Moly | SA335 Grade P9 9% Chrome; 1% Moly |

| CHROME- MOLY ALLOY STEEL PIPE NOMINAL WALL SEAMLESS | A335 Grade P91 9% Chrome; 1% Moly + trace elements | SA335 P91 A335 9% Chrome; 1% Moly + trace elements |

Alloy Steel P91 Chrome Moly Welded Pipe

| ASTM A335 P91 Pipe Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| ASTM A335 P91 Seamless Pipe (Custom Sizes) | 1/2" NB - 60" NB | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Custom |

| ASTM A335 P91 ERW Pipe (Custom Sizes) | 1/2" NB - 24" NB | As per requirement | Custom |

| ASTM A335 P91 Welded Pipe (in Stock + Custom Sizes) | 1/2" NB - 24" NB | As per requirement | Custom |

| ASTM A335 High Pressure P91 Boiler Pipe | 16" NB - 100" NB | As per requirement | Custom |

Products of Alloy Steel Gr.P91 Pipe

| High Quality Grade P91 Alloy Steel Pipe | ASTM A335 P91 Pipe Dealer |

| Alloy A335 P91 Seamless Square Pipe | Grade P91 Hydraulic Pipe Exporter |

| AISI P91 ERW pipe | ASTM A335 P91 Pipe |

| Astm A335 Gr P91 Equivalent | ASTM A335 P91 Material |

| Sa335 P91 Material | Sa335 Grade P91 Pipe |

| ASTM A335 P91 Pipe Price | ASTM A335 P91 Pipe Weight |

| ASTM A335 Gr P91 Pipe | A335 Gr P91 Equivalent Material |

| Asme A335 P91 Pipe | Sa335 P91 Pipe |

| ASTM A335 P91 Pipe | ASTM A335 Gr P91 Pipe |

| A335 P91 Material | Astm A335 Gr P91 Pipe |

| A335 P91 Welded Pipe | Astm A335 P91 Temperature Limit |

| Alloy Steel P91 Pipes | P91 Alloy Steel A335 Pipe |

| ASTM A335 grade P91 Pipe | ASTM A335 P91 ASTM A335 P91 Square hollow section |

| High Pressure P91 Boiler Pipe | ASME SA335 P91 Alloy Steel Rectangular Pipe |

| grade P91 Alloy Steel Hydraulic Pipe | Alloy Steel Gr P91 LSAW Pipe |

| ASME SA 335 Alloy Steel P91 Seamless Pipe | IBR Alloy Steel P91 Pipe |

| P91 Alloy Pipe | ASME SA / ASTM A335 P91 Pipe |

| ASTM A335 P91 Pipe | SA335 P91 pipe |

| Astm A335 P91 | Astm A335 Gr P91 |

| Alloy Steel P91 Pipe | P91 Alloy Steel A335 Pipe |

| AISI P91 ERW pipe | ASTM A335 P91 Pipe |

| ASTM A335 grade P91 Pipe | ASTM A335 P91 ASTM A335 P91 Square hollow section |

| High Quality Grade P91 Alloy Steel Pipe | ASTM A335 P91 Pipe Dealer |

| grade P91 Alloy Steel Hydraulic Pipe | Alloy Steel Gr P91 LSAW Pipe |

| P91 Alloy Pipe | ASME SA / ASTM A335 P91 Pipe |

| ASME SA 335 Alloy Steel P91 Seamless Pipe | IBR Alloy Steel P91 Pipe |

| Alloy A335 P91 Seamless Square Pipe | Grade P91 Hydraulic Pipe Exporter |

| High Pressure P91 Boiler Pipe | ASME SA335 P91 Alloy Steel Rectangular Pipe |

Weight chart of ASME SA335 High Pressure Alloy Pipe

| P91 Pipe Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot |

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 |

| 0.147 | 0.546 | 1.09 | ||

| 0.188 | 0.464 | 1.31 | ||

| 0.294 | 0.252 | 1.72 | ||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 |

| 0.154 | 0.742 | 1.48 | ||

| 0.219 | 0.612 | 1.95 | ||

| 0.308 | 0.434 | 2.44 | ||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 |

| 0.179 | 0.957 | 2.17 | ||

| 0.250 | 0.815 | 2.85 | ||

| 0.358 | 0.599 | 3.66 | ||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 |

| 0.191 | 1.278 | 3.00 | ||

| 0.250 | 1.160 | 3.77 | ||

| 0.382 | 0.896 | 5.22 | ||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 |

| 0.200 | 1.500 | 3.63 | ||

| 0.281 | 1.338 | 4.86 | ||

| 0.400 | 1.100 | 6.41 | ||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 |

| 0.154 | 2.067 | 3.66 | ||

| 0.218 | 1.939 | 5.03 | ||

| 0.250 | 1.875 | 5.68 | ||

| 0.281 | 1.813 | 6.29 | ||

| 0.344 | 1.687 | 7.47 | ||

| 0.436 | 1.503 | 9.04 | ||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 |

| 0.203 | 2.469 | 5.80 | ||

| 0.216 | 2.443 | 6.14 | ||

| 0.250 | 2.375 | 7.02 | ||

| 0.276 | 2.323 | 7.67 | ||

| 0.375 | 2.125 | 10.02 | ||

| 0.552 | 1.771 | 13.71 | ||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 |

| 0.156 | 3.188 | 5.58 | ||

| 0.172 | 3.156 | 6.12 | ||

| 0.188 | 3.124 | 6.66 | ||

| 0.216 | 3.068 | 7.58 | ||

| 0.250 | 3.000 | 8.69 | ||

| 0.281 | 2.938 | 9.67 | ||

| 0.300 | 2.900 | 10.26 | ||

| 0.438 | 2.624 | 14.34 | ||

| 0.600 | 2.300 | 18.6 | ||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 |

| 0.226 | 3.548 | 9.12 | ||

| 0.250 | 3.500 | 10.02 | ||

| 0.281 | 3.438 | 11.17 | ||

| 0.318 | 3.364 | 12.52 | ||

| 0.636 | 2..728 | 22.87 | ||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 |

| 0.156 | 4.188 | 7.24 | ||

| 0.188 | 4.124 | 8.67 | ||

| 0.203 | 4.094 | 9.32 | ||

| 0.219 | 4.062 | 10.02 | ||

| 0.237 | 4.026 | 10.80 | ||

| 0.250 | 4.000 | 11.36 | ||

| 0.281 | 3.938 | 12.67 | ||

| 0.312 | 3.876 | 13.97 | ||

| 0.337 | 3.826 | 15.00 | ||

| 0.438 | 3.624 | 19.02 | ||

| 0.531 | 3.438 | 22.53 | ||

| 0.674 | 3.152 | 27.57 | ||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 |

| 0.219 | 5.125 | 12.51 | ||

| 0.258 | 5.047 | 14.63 | ||

| 0.281 | 5.001 | 15.87 | ||

| 0.312 | 4.939 | 17.51 | ||

| 0.344 | 4.875 | 19.19 | ||

| 0.375 | 4.813 | 20.80 | ||

| 0.500 | 4.563 | 27.06 | ||

| 0.625 | 4.313 | 32.99 | ||

| 0.750 | 4.063 | 38.59 | ||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 |

| 0.134 | 6.357 | 9.30 | ||

| 0.156 | 6.313 | 10.79 | ||

| 0.188 | 6.249 | 12.94 | ||

| 0.203 | 6.219 | 13.94 | ||

| 0.219 | 6.187 | 15.00 | ||

| 0.250 | 6.125 | 17.04 | ||

| 0.280 | 6.065 | 18.99 | ||

| 0.312 | 6.001 | 21.06 | ||

| 0.344 | 5.937 | 23.10 | ||

| 0.375 | 5.875 | 25.05 | ||

| 0.432 | 5.761 | 28.60 | ||

| 0.500 | 5.625 | 32.74 | ||

| 0.562 | 5.501 | 36.43 | ||

| 0.625 | 5.375 | 40.09 | ||

| 0.719 | 5.187 | 45.39 | ||

| 0.864 | 4.897 | 53.21 | ||

| 1.000 | 4.625 | 60.13 | ||

| 1.125 | 4.375 | 66.14 |