A335 gr P11 Welded Pipe, Alloy Steel P11 Seamless Pipe stockist in India

Alloy steel P11 pipes are one finest quality stainless steel built with key components of chromium oxide and molybdenum, which are the addition to the basic nickel alloy. Where the chrome increases the alloys’ high-temperature strength and enhances its tensile and yields strength and hardness in normal conditions. The chromium also increases its reliability with oxidation resistance and protects the nickel-iron alloy from other basic corrosions. Simultaneously, molybdenum helps increase the metal's overall strength and provides resistance from crevice corrosives in extreme conditions. These components help the alloy from the formation of grains and make it less susceptible to embrittlement. Molybdenum is one of the most effective additives that provide creep resistance in high temperatures, enhance better resistance to various corrosions, and are reluctant to pit.

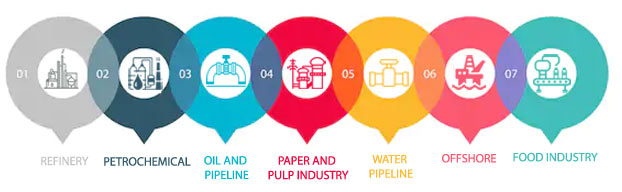

While the alloy steel P11 pipes have 30% elongation along with 205 MPa of yield strength and 415 MPa of tensile strength, which is common among many other steel grades. The wall thickness of the P11 alloy ranges from 2 mm to 14 mm and different sizes ranging from ½” NB to 36” NB. However, it has many forms like round, square, rectangular, hydraulic, coiled, U shape, and pancake. The alloy also derives other chemical elements like manganese and carbon which add more substance to the material. The P11 grade of alloy provides great sustainability with its anti-corrosive properties and has a wide industrial application. It is used in petrochemical industries, electric power generation plants, oil, and gas refineries, automobile industries, and has many other usages. It is durable in various environmental conditions, works well under pressure situations, and has a high temperature bearing capacity.

Along with the other steel products, the P11 alloy steels pipes can also be customized according to the customer’s needs in various thicknesses, shoes, sizes, dimensions, and length. We at LG pipes and tubes only delivers trusted products with all the required certifications. Our products go under strict quality checks leaving no space for defects and are examined under expert supervision. We believe in excellent service at affordable rates and has a huge inventory to fulfill all the customers requirements.

Table of contents

- Specification of A335 P5 Pipe

- UNS K41245 Pipe Price in India

- Application of Alloy Steel Grade P5 Pipe

- Types of P5 Alloy Steel A335 Pipe

- ASTM A335 P5 Pipe chemical composition

- Mechanical properties of Alloy Steel P5 Pipe

- ASTM SA335 P5 Pipe Equivalent

- A335 Alloy Steel P5 Seamless Pipe

- Products of Alloy Steel Gr.P5 Pipe

- Weight chart of ASME SA335 High Pressure Alloy Pipe

- Alloy Steel P5 Chrome Moly Welded Pipe

Specification of A335 P11 Pipe

| ASME SA335 GR P11 Pipe Size | 1/2” NB to 36” NB |

| A335 GR P11 Pipe Standard | ASTM A335 P11, SA335 P11 (with IBR Test Certificate) |

| A335 Grade P11 Pipe Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| P11 Alloy Pipe Thickness | 3-12mm |

| P11 Alloy Steel Pipe Tolerance |

Cold drawn pipe: +/-0.1mm

Cold rolled pipe: +/-0.05mm

|

| ASTM A335 P11 Pipe Origin | European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| ASTM A335 P11 Pipe Type | Seamless / ERW / Welded / Fabricated |

| Craft | Cold rolled and Cold drawn |

| Alloy Steel P11 Pipe Length | Standard Double & In Cut length also. |

| ASTM A335 P11 Pipe available in Form of | Round, Square, Rectangular, Hydraulic Etc. |

| Specialized in | Large Diameter ASTM A335 P11 Pipe |

| ASTM A335 P11 Pipe End | Plain End, Beveled End, Treaded |

| Application | Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

| Additional Testing | NACE MR 0175, NACE TM0177, NACE TM0284, HIC TEST, SSC TEST, H2 SERVICE, IBR, etc. |

UNS K11597 Pipe Price in India

| Size | MSL Make | JSL Make | ISMT make |

|---|---|---|---|

|

1/2"

|

4,264.71

|

4,272.06

|

4,257.35

|

|

3/4"

|

4,044.12

|

4,051.47

|

4,036.76

|

|

1"

|

3,897.06

|

3,904.41

|

3,889.71

|

|

1.25"

|

3,852.94

|

3,860.29

|

3,845.59

|

|

1.5"

|

3,750.00

|

3,757.35

|

3,742.65

|

Application of Alloy Steel Grade P11 Pipe

Types of A335 P11 Pipe Suppliers

ASME SA335 P11 Pipe

ASTM A335 P11 Pipe

A335 P11 Pipe

SA335 P11 Pipe

ASTM A335 Grade P11 Rectangular Tube

ASTM A335 GR P11 Pipe

SA335 Grade P11 Seamless Pipe

UNS K11597 Welded Pipe

SA335 GR P11 Boiler Pipe

ASTM A335 Alloy Steel P11 ERW Pipe

ASTM A335 grade P11 Pipes

ASME SA335 Grade P11 Alloy Steel Pipe

Alloy Steel P11 Chrome Moly Pipe chemical composition

| Alloy Steel P11 | C | Cr | S | Si | Mn | Mo | P |

| 0.05 – 0.15 | 1.00 – 1.50 | 0.025 max | 0.50 – 1.00 | 0.30 – 0.60 | 0.44 – 0.65 | 0.025 max |

Alloy Steel Grade P11 Pipe mechanical properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation |

| 415 min | 205 min | 30 min |

SA335 P11 Pipe Tensile Requirements

| Seamless | |||||

|---|---|---|---|---|---|

| P-5 | P-9 | P-11 | P-22 | P-91 | |

| Tensile Strength, min., psi | |||||

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | |||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

Alloy Steel P11 Pipe Equivalent

ASTM A335 Alloy Steel P11 Pipe equivalent

Alloy Steel P11 Pipes Standard: ASTM A335, ASME SA335

Equivalent Standards: EN 10216-2, ASTM A213, ASME SA213, GOST 550-75, NBR 5603

Alloy Steel Material: P11, K11597

Schedule: SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

| ASTM | ASME | Equivalent Material | JIS G 3458 | UNS | BS | DIN | ISO | ABS | NK | LRS |

|---|---|---|---|---|---|---|---|---|---|---|

| A335 P11 | SA335 P11 | T11 | STPA 23 | K11597 | 3604 P1 621 | - | - | ABS 11 | KSTPA 23 | - |

A335 Alloy Steel P11 Seamless Pipe suppliers in india

Alloy Steel P11 Chrome Moly Welded Pipe

| ASTM A335 P11 Pipe Types | Out diameter | Wall thickness | Length |

|---|---|---|---|

| ASTM A335 P11 Seamless Pipe (Custom Sizes) | 1/2" NB - 60" NB | SCH 5 / SCH 10 / SCH 40 / SCH 80 / SCH 160 | Custom |

| ASTM A335 P11 ERW Pipe (Custom Sizes) | 1/2" NB - 24" NB | As per requirement | Custom |

| ASTM A335 P11 Welded Pipe (in Stock + Custom Sizes) | 1/2" NB - 24" NB | As per requirement | Custom |

| ASTM A335 High Pressure P11 Boiler Pipe | 16" NB - 100" NB | As per requirement | Custom |

Products of Alloy Steel Gr.P11 Pipe

| A335 Grade P11 Pipe Sch 40 | A335 GR P11 Scaffold Pipe |

| IBR Certified Grade P11 Pipes | P11 Grade Steel Plain End Pipe |

| ASTM A335 P11 Hydraulic Pipe | 4 Inch Alloy Steel P11 Pipe |

| SA335 P11 Beveled End Pipe | 3 Inch P11 Alloy Steel Pipe |

| SA 335 GR P11 Cut Length of Pipe | ASTM A335 P11 Alloy Steel Threaded Pipe |

| ASME SA335 Grade P11 IBR Pipes | SA335 Grade P11 Rectangular Pipe |

| ASTM A335 P11 Double Random Pipe | ASTM A335 Grade P11 Pipe For Oil and Gas Industry |

| A335 GR P11 Pipe Sch 60 | Alloy Steel A335 P11 Sch40 Pipe |

| SA335 P11 Plain End Drill Pipe | Steel P11 Pipe |

| ASME SA335 GR P11 IBR Approved Pipes | ASME SA335 Grade P11 Single Random Length Pipe |

| Alloy Steel A335 P11 Pipe Sch 80 Nace | P11 Alloy Steel Nuclear Power Plants Steam Pipes |

| Steel Grade P11 Pipe Sch 20 | ASTM A335 P11 Alloy Steel Pipe For Oil Tank |

| Large Diameter P11 Alloy Pipe Sleeve | A335 Grade P11 Plain End Beveled Pipe |

| Nuclear Power Plants ASME SA335 GR P11 Pipes | SA335 P11 IBR Steam Pipe |

| Alloy Steel A335 P11 IBR Piping | ASTM A335 GR P11 Oil & Gas Pipeline |

| SA 335 GR P11 IBR Piping Material | SA335 Grade P11 Pipe For Oil Rig |

| ASME SA335 Grade P11 Pipe For Oil and Gas | ASTM A335 P11 Alloy Steel IBR and Non IBR Piping |

| IBR Approved P11 Steel Pipe | SA335 GR P11 IBR Pipe |

| Steel P11 IBR Steam Piping | SA 335 GR P11 Pipe Sleeve For Gas Pipe |

| SA 335 GR P11 Oil & Gas Piping | Steel P11 Pipe For Liquid Nitrogen |

| A335 P11 Pipe For Liquid Propane | ASME SA335 GR P11 Fill Pipe for Oil Tank |

| Grade P11 Fluid Pipe Material | Steel Grade P11 IBR Pipe Material |

| ASTM A335 GR P11 Pipe Sleeve | Grade P11 Pipe For Gas Line |

| ASME SA335 GR P11 Gas Pipe Sleeve | ASTM A335 P11 Fluid Pipe |

| P11 Steel Pipe Sleeve Material | P11 Alloy Flexible Pipe For Conveying A Liquid or Gas |

| SA335 GR P11 Pipe Conveying Fluid Or Gas | Grade P11 Pipe For Water |

| ASTM A335 Grade P11 Seamless Pipe | ASTM A335 GR P11 IBR Grade Pipe |

| A335 Grade P11 Welded Pipe | SA335 Grade P11 Boiler Pipes |

| Steel Grade P11 Drill Pipe | ASTM A335 GR P11 Seamless Pipes |

| SA335 Grade P11 Piping Material | Alloy Steel A335 P11 Welded Pipes |

| A335 GR P11 IBR Pipe Line | ASME SA335 Grade P11 Erw Pipes |

| ASME SA335 P11 Pipe | IBR Alloy Steel SA335 P11 Pipe |

| P11 Alloy Steel Boiler Pipe | ASTM A335 Grade P11 High Pressure Pipe |

| ASME SA335 P11 Material | P11 Grade Steel Rolled Pipe |

| ASTM A335 P11 Pipe Material | A335 Grade P11 Pipes |

| SA335 GR P11 High Pressure Pipes | P11 Grade Steel IBR Steam Pipe Line |

| ASME SA335 P11 Rolled Pipes | Alloy Steel P11 Round Pipe |

| ASTM A335 Grade P11 Flexible Pipe | P11 Alloy Steel Square Pipe |

| Alloy Steel P11 Erw Pipe | A335 GR P11 Used Pipe |

| P11 Grade Steel Large Diameter Pipes | ASME SA335 P11 Radiator Pipe |

| Steel Grade P11 Large Diameter Pipe Clamps | SA335 GR P11 Turbo Pipe |

Weight chart of ASME SA335 High Pressure Alloy Pipe

| P11 Pipe Size NPS | Pipe O.D. | Wall Thickness | Pipe I.D. | Weight per Foot |

| 1/2 | 0.84 | 0.109 | 0.622 | 0.85 |

| 0.147 | 0.546 | 1.09 | ||

| 0.188 | 0.464 | 1.31 | ||

| 0.294 | 0.252 | 1.72 | ||

| 3/4 | 1.05 | 0.113 | 0.824 | 1.13 |

| 0.154 | 0.742 | 1.48 | ||

| 0.219 | 0.612 | 1.95 | ||

| 0.308 | 0.434 | 2.44 | ||

| 1 | 1.315 | 0.133 | 1.049 | 1.68 |

| 0.179 | 0.957 | 2.17 | ||

| 0.250 | 0.815 | 2.85 | ||

| 0.358 | 0.599 | 3.66 | ||

| 1 1/4 | 1.66 | 0.140 | 1.380 | 2.27 |

| 0.191 | 1.278 | 3.00 | ||

| 0.250 | 1.160 | 3.77 | ||

| 0.382 | 0.896 | 5.22 | ||

| 1 1/2 | 1.90 | 0.145 | 1.610 | 2.72 |

| 0.200 | 1.500 | 3.63 | ||

| 0.281 | 1.338 | 4.86 | ||

| 0.400 | 1.100 | 6.41 | ||

| 2 | 2.375 | 0.109 | 2.157 | 2.64 |

| 0.154 | 2.067 | 3.66 | ||

| 0.218 | 1.939 | 5.03 | ||

| 0.250 | 1.875 | 5.68 | ||

| 0.281 | 1.813 | 6.29 | ||

| 0.344 | 1.687 | 7.47 | ||

| 0.436 | 1.503 | 9.04 | ||

| 2 1/2 | 2.875 | 0.120 | 2.635 | 3.53 |

| 0.203 | 2.469 | 5.80 | ||

| 0.216 | 2.443 | 6.14 | ||

| 0.250 | 2.375 | 7.02 | ||

| 0.276 | 2.323 | 7.67 | ||

| 0.375 | 2.125 | 10.02 | ||

| 0.552 | 1.771 | 13.71 | ||

| 3 | 3.50 | 0.120 | 3.260 | 4.34 |

| 0.156 | 3.188 | 5.58 | ||

| 0.172 | 3.156 | 6.12 | ||

| 0.188 | 3.124 | 6.66 | ||

| 0.216 | 3.068 | 7.58 | ||

| 0.250 | 3.000 | 8.69 | ||

| 0.281 | 2.938 | 9.67 | ||

| 0.300 | 2.900 | 10.26 | ||

| 0.438 | 2.624 | 14.34 | ||

| 0.600 | 2.300 | 18.6 | ||

| 3 1/2 | 4.0 | 0.120 | 3.760 | 4.98 |

| 0.226 | 3.548 | 9.12 | ||

| 0.250 | 3.500 | 10.02 | ||

| 0.281 | 3.438 | 11.17 | ||

| 0.318 | 3.364 | 12.52 | ||

| 0.636 | 2..728 | 22.87 | ||

| 4 | 4.5 | 0.120 | 4.260 | 5.62 |

| 0.156 | 4.188 | 7.24 | ||

| 0.188 | 4.124 | 8.67 | ||

| 0.203 | 4.094 | 9.32 | ||

| 0.219 | 4.062 | 10.02 | ||

| 0.237 | 4.026 | 10.80 | ||

| 0.250 | 4.000 | 11.36 | ||

| 0.281 | 3.938 | 12.67 | ||

| 0.312 | 3.876 | 13.97 | ||

| 0.337 | 3.826 | 15.00 | ||

| 0.438 | 3.624 | 19.02 | ||

| 0.531 | 3.438 | 22.53 | ||

| 0.674 | 3.152 | 27.57 | ||

| 5 | 5.563 | 0.188 | 5.187 | 10.80 |

| 0.219 | 5.125 | 12.51 | ||

| 0.258 | 5.047 | 14.63 | ||

| 0.281 | 5.001 | 15.87 | ||

| 0.312 | 4.939 | 17.51 | ||

| 0.344 | 4.875 | 19.19 | ||

| 0.375 | 4.813 | 20.80 | ||

| 0.500 | 4.563 | 27.06 | ||

| 0.625 | 4.313 | 32.99 | ||

| 0.750 | 4.063 | 38.59 | ||

| 6 | 6.625 | 0.109 | 6.407 | 7.59 |

| 0.134 | 6.357 | 9.30 | ||

| 0.156 | 6.313 | 10.79 | ||

| 0.188 | 6.249 | 12.94 | ||

| 0.203 | 6.219 | 13.94 | ||

| 0.219 | 6.187 | 15.00 | ||

| 0.250 | 6.125 | 17.04 | ||

| 0.280 | 6.065 | 18.99 | ||

| 0.312 | 6.001 | 21.06 | ||

| 0.344 | 5.937 | 23.10 | ||

| 0.375 | 5.875 | 25.05 | ||

| 0.432 | 5.761 | 28.60 | ||

| 0.500 | 5.625 | 32.74 | ||

| 0.562 | 5.501 | 36.43 | ||

| 0.625 | 5.375 | 40.09 | ||

| 0.719 | 5.187 | 45.39 | ||

| 0.864 | 4.897 | 53.21 | ||

| 1.000 | 4.625 | 60.13 | ||

| 1.125 | 4.375 | 66.14 |